Automation is often seen as a crucial part of manufacturing, but it’s not a one-size-fits-all solution. In fact, sometimes businesses can achieve solid results without automating their processes. This was highlighted by Hari Parthasarathi, an expert from 3M, who stressed the importance of evaluating automation on a case-by-case basis rather than jumping into costly investments.

Understanding Automation

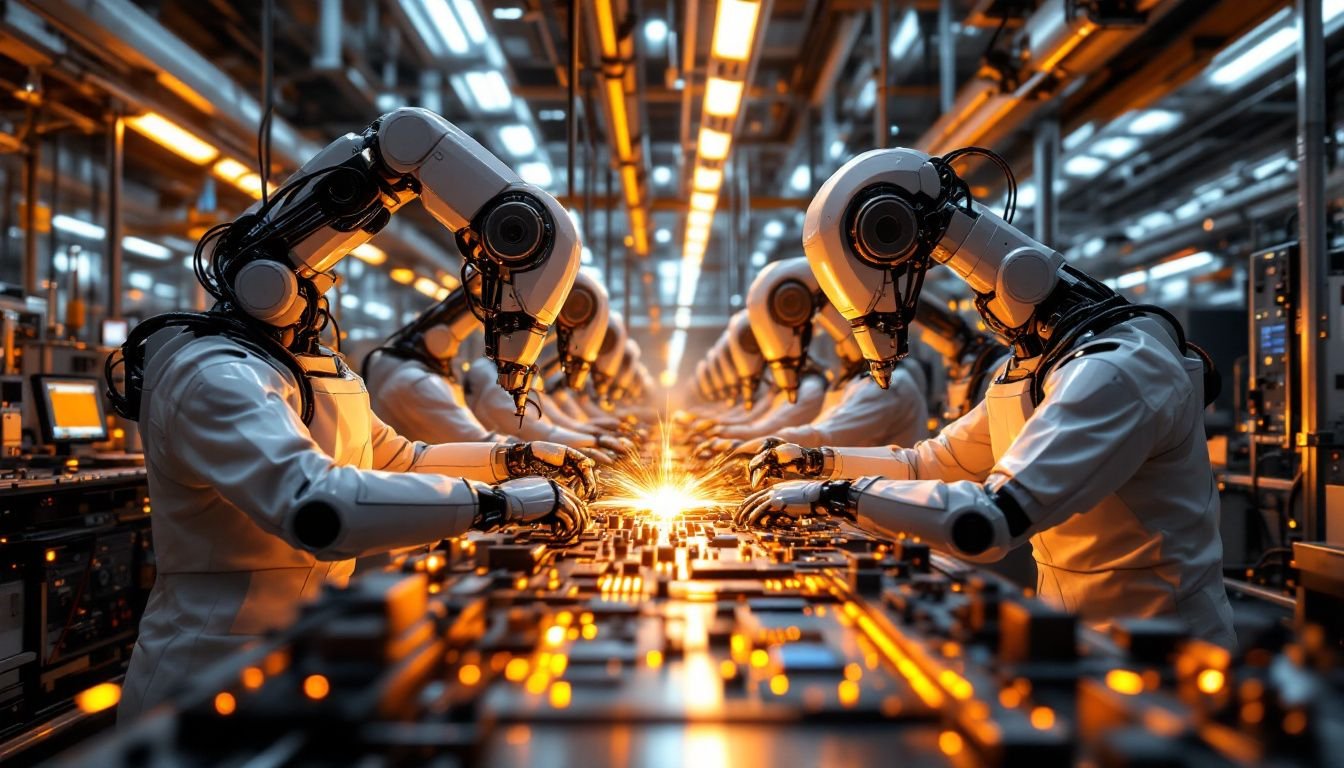

Automation can make operations faster and more efficient. However, it’s important to recognize that not every company needs it. Some existing processes may already be effective. Companies like 3M have been in the automation field for over a century, having established a significant presence in India since 1987. Recently, 3M launched a robotics lab in Bengaluru, showcasing its commitment to innovation.

India’s Manufacturing Scene

The industrial automation market in India is booming. It’s expected to reach $15.2 billion in 2024, with projections of exceeding $29 billion by 2029. India’s manufacturing landscape is diverse, ranging from small businesses to large international firms. However, many of these businesses prioritize cost-effective solutions over advanced and expensive technologies.

Parthasarathi highlights the transformation of India into a manufacturing hub, supported by initiatives like ‘Make in India’ and growing global interest. Over the years, manufacturing has been seen as secondary compared to IT and services, but that is changing.

Types of Automation

In manufacturing, there are two main types of automation:

- Fixed Automation: Used for large production volumes of identical products.

- Robotic Automation: Employed for complex parts where flexibility is needed.

3M collaborates with various partners to customize automation systems tailored to specific needs. For instance, they’ve seen tenfold productivity increases in some segments through effective automation. Yet, they emphasize proof of concept to ensure lasting value.

Challenges in Adoption

Even though many companies recognize the benefits of automation, the adoption in India can be slow. Reasons include:

- High implementation costs.

- Lack of skilled workforce.

- Uncertainty about the long-term benefits of automation.

3M believes that automation should enhance human skills, not replace them. They stress a balanced, thoughtful approach to integrating automation while upskilling workers.

The Future with Humanoids

Humanoid robots are becoming a reality in manufacturing. Companies like BMW and Amazon are already using them. Parthasarathi mentions that while humanoids could play a significant role in future automation at 3M, their integration will not happen immediately. They are currently focusing on solutions that can streamline processes, such as automated inspections for automotive paint defects.

Final Thoughts

While automation comes with its advantages, it is crucial to evaluate its necessity and effectiveness for specific operations. Businesses should consider their unique needs, technology costs, and workforce skills before fully diving into automation. By doing so, they can ensure that their investments bring genuine benefits and enhance productivity.

As the manufacturing landscape evolves, companies will have to reflect on the best ways to integrate technology responsibly. The goal should be to foster collaboration between humans and machines for a more efficient future.